Project - FX Crown Moderator

Silent Thunder Ordnance

FX Crown with a flow-through tesla gas diode suppressor.

Thanks to a legal ruling, airgun moderators are legal in the United States. This is probably why essentially all airguns now come with one. For most users though, the stock moderator is insufficient to achieve the level of suppression they desire. This was the case with my FX Crown. Strap in, this is going to be a long one. Not sure if you want to suffer through so many lines of crawling ants? Read the conclusion (final paragraph) first, and then decide if you want to know more about the journey that lead to the destination.

In another life, I did design work on firearm suppressors. Experience tells me they are deceptively simple devices; the devil really is in the details. And this runs the gamut from effects on accuracy, size constraints, sound attenuation, and tone. Given huge suppressor volume, it is relatively easy to build something quiet, so the most significant trick is making a quiet design small. The second trick though is accuracy, many extremely quiet designs cause some level of projectile destabilization and associated inaccuracy. Making a complete package which is desirable and effective is just the sort of fun challenge I’m all about.

Enter the FX Crown. Great gun, but even with the shroud extended it has quite a bark (and looks goofy). Airgun moderators have several distinct advantages and disadvantages over firearm ones. The most notable disadvantage is that the projectiles are lighter, have lower sectional density, are more subject to turbulence, and all this makes them easier to destabilize. That is the hard part. The easy part is that the exhaust gasses are cool and the total system pressure and volume at the muzzle are relatively low. This opens up a LOT more materials and manufacturing technologies. It also means moderators can be much lighter weight. The Final major advantage is the legality of airgun moderators, making complete units, parts, etc all much easier to handle.

Original Tesla Fluid Valve patent ref. en.wikipedia.org/wiki/Tesla_valve

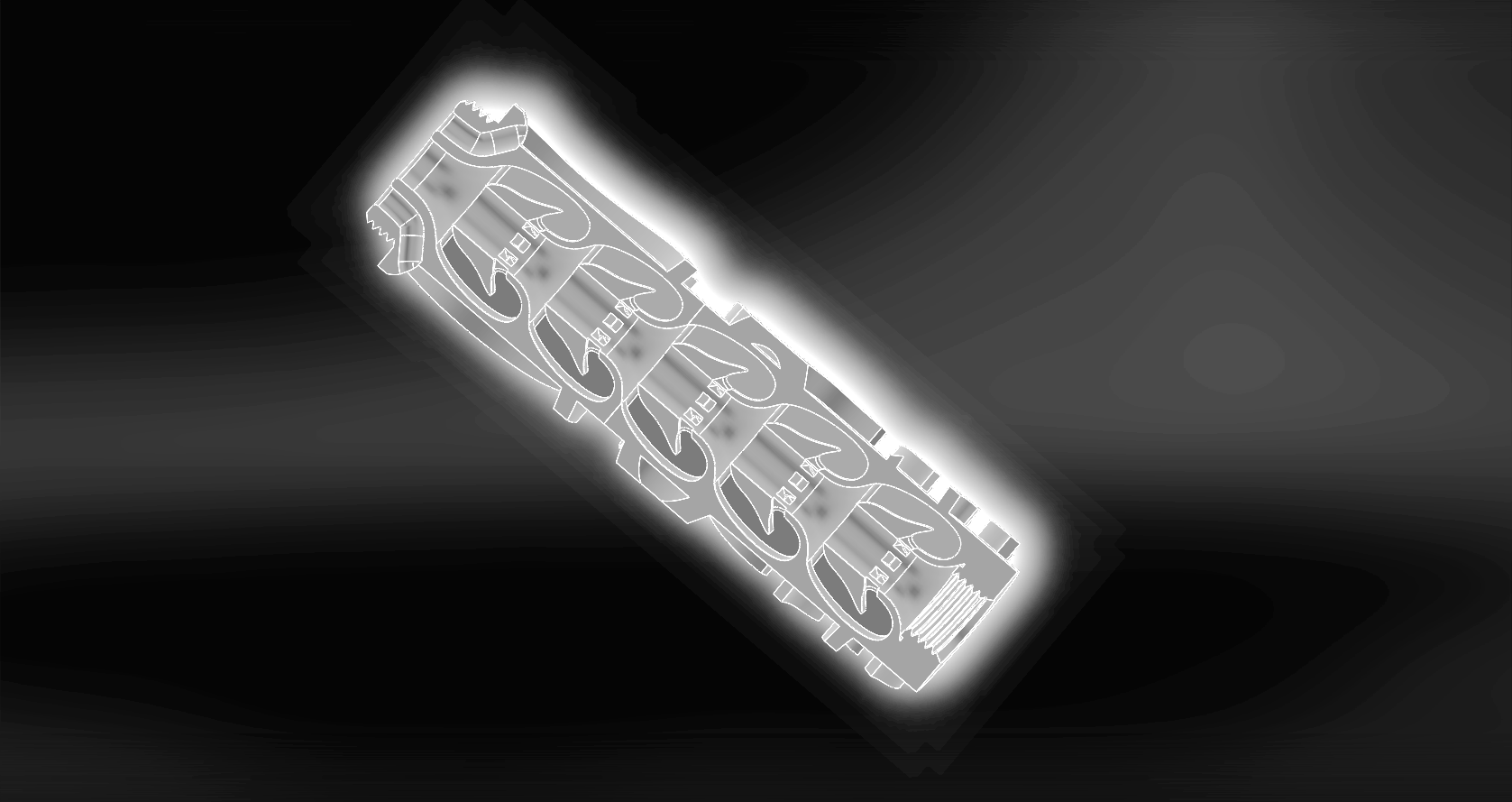

The FX Crown has a somewhat unusual design which provides its own challenges and opportunities. For those unaware, there is a muzzle brake attached to the end of the barrel, and any moderator must be screwed not to this but to the shroud which surrounds it. This means you already have your blast baffle taken care of, as well as an existant pressure reservoir to deal with. It so means your thread will be the unique M27x1.5, not exactly an every day size. An idea I’d long kicked around but never tested was that of the Tesla Gas Diode. A diode is essentially something which allows free movement in one direction, and resists movement in the other. A common use everyone is likely familiar with is the LED or Light Emitting Diode, which is a one-way valve for electrons that produces light as a side effect. While the original design was for fluid only, and didn’t need anything to pass down the bore, in theory it could be readily adapted to be radially symmetric and have a straight bore large enough to pass a projectile. The concept simply splits and reflexes gas back on itself to create resistance which scales, the harder you blow the more it resists. Thus the idea is to restrict the forward flow of gas from the muzzle of the airgun, while allowing it to freely travel rearward back toward the barrel.

The flow-through gas diode suppressor concept, clearly showing the internal chambers where the gas is reflexed back on itself to limit flow. Also visible in this cross section, at the extreme rear, are two of the eight flow tubes which pick up air from the rear of the moderator and jet it around the outside.

There is a second element to my design hypothesis here though. Suppressors are all stuck at a general performance class based on size, as that size is the total volume; no matter how efficient your suppressor is, you can only eat as much gas as your can’s volume….. or can you? OSS has popularized this concept recently, although Brugger and Thomet to my knowledge is its originator, predating OSS by well over a decade. The latter doesn’t really publicize their work in the United States or really much at all to my knowledge, and while the former does their designs (to put it bluntly) are way too large, heavy, and loud to be relevant or even demonstrate the forward-vented-volume concept. Their marketing is not centered around sound attenuation, but minimizing backpressure in automatic weapon actions, and to put it politely I believe them. There are a few other users of non-fixed-volume designs in airguns. Air Arms has, at least for the last few years, cut vents into their actions where the shroud meets. These create quite the startling blast to your spotter or anyone else next to you. Huggett also has moderators with mesh screens and vents over the blast area, although their cores are simply a felt/foam/whatever material over a rigid structure to protect it, very similar to DonnyFL designs.

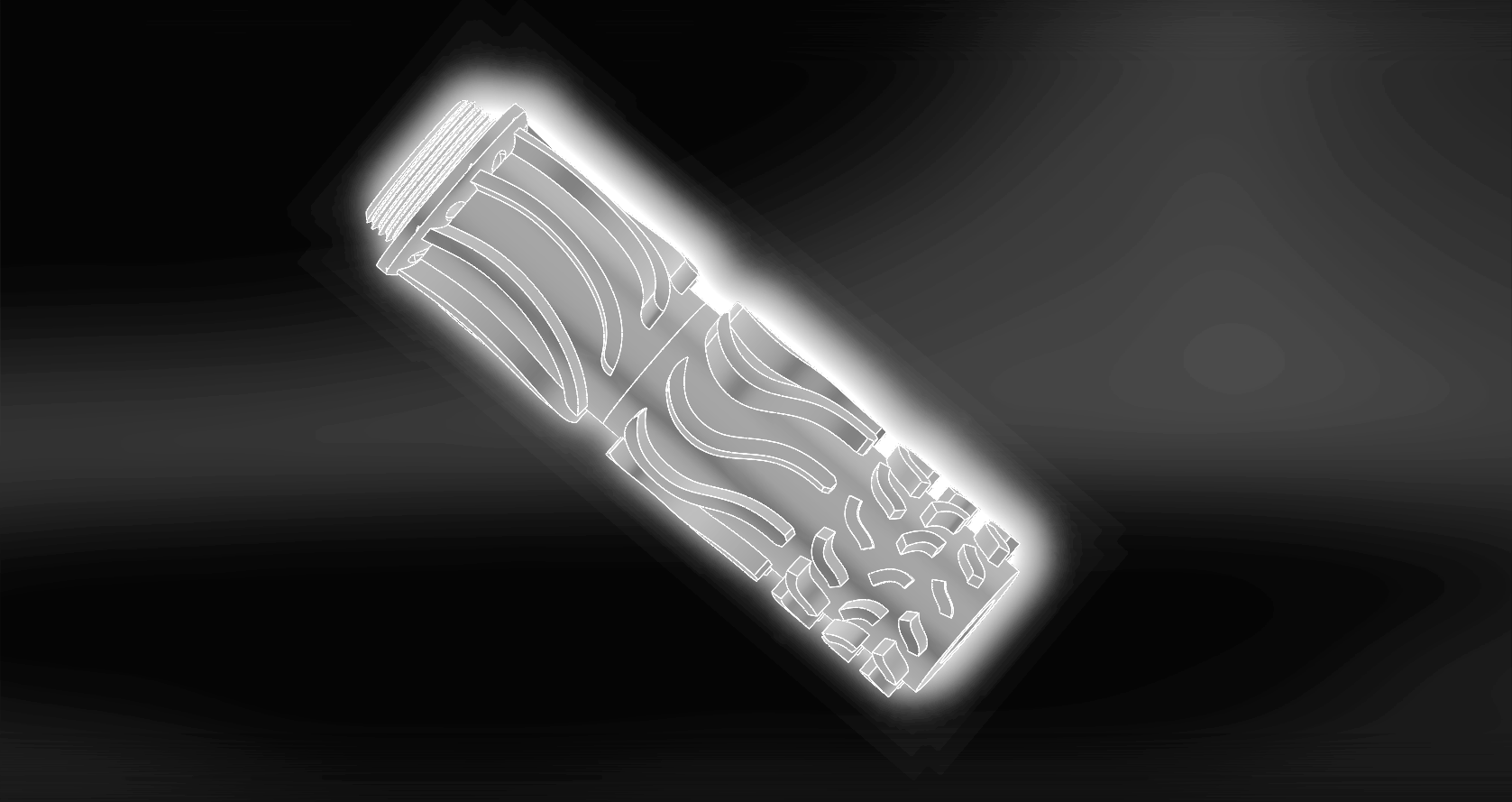

The outer flow path. Visible at the top left, on the toroidal mating face, are the vents which will dump air into this area. Essentially everything visible here will be covered when the moderator is in use, as it slips into a carbon tube and is capped.

So I wanted an unlimited volume design, something which will continuously vent gas to increase its efficiency. It is comparatively easy to disrupt a pressure wave if you can physically obstruct it. So to take some pressure, pun intended, off the linear gas diodes I wanted to create an outer chamber inside the suppressor which would allow relatively free flow of gas, while breaking up the pressure front, to allow a small moderator to ingest a lot of flow with minimal sound. Because of the size of the threading, we actually have room to pick up this gas at the very rear of the moderator, essentially tapping it off after the blast baffle courtesy of FX. This is the second half of the concept, once gas pressure has equalized in a given section it will vent more effectively rearward toward the gun, which will will then be taken up by the outer flow tubes and pass through the outer suppressor chamber. This outer chamber requires no in-line flow, so can effectively disrupt the sound. The outer chamber itself is sealed by the tube, in this case a carbon fiber tube. Mating surfaces at the rear and cap are toroidal, which automatically produces alignment with the ends of the carbon tube. This leads nicely to the muzzle cap.

Cap design is its own entire area of study. While they seem simple, a cap can have a significant affect on the propagation of sound out of the loud end. Typically disruptors and channels on the surface are desirable, to redirect sound forward and to break up any wave fronts which emerge, however for the purposes of this initial testing I wanted to use a simple cap design which wouldn’t advantage or disadvantage a particular design, and also minimized overall length. Furthermore, caps being readily exchanged, I can swap this trivially later.

A simple cap. Venting along the perimeter, and a hole for the pellet in the middle. This design uses the same tool for installation/removal as the factory FX shroud.

For the flow-through designs the cap is quite simple. Threaded at the end, it screws to the front of the core creating a semi-seal. Outside that there are six holes of equal size and spacing to FX’s original shroud cap, so whatever tool was used to remove that can be used to install this. These are through-holes so as to provide further breathing for the outer chamber, although that is a secondary function. The outer line of holes are oval in aperture, but have an offset path. De-torquing of airgun moderators from firing cycles isn’t an issue, however this will serve to generate torque assuring everything remains tight. It will also act as one final disruption of the air as it exits. Simple to implement, and potentially advantageous. The rear face that mates with the carbon tube is, as mentioned previously, is toroidal as this naturally produces good contact and alignment.

Here we can see the offset path of the outer vents, which serve to swirl the gasses as they exit the moderator.

Put simply, the concept here is that the central core aerodynamically restricts flow to muffle the initial blast while the outer core allows flow as freely as possible while disrupting the pressure front responsible for the sound…… at least in theory, in practice things can be somewhat different.

Here is the pickle: theory is where you understand things, but nothing works. Practice is where some things work, but you don’t understand why. I have a habit of combining theory and practice, where nothing works and I have no idea why. A hallmark of good science is a control, in essence a way to know if your hypothesis is valid or not. Instead of simply one control though, for optimum scienticiousness, I want three. I’ll then call up another buddy from STO to dig out the old impulse sound meter, an exotic device unlike conventional sound meters in that it measures peaks from short pressure waves rather than continuous sound, and test all four configurations. Speaking of which, all four configurations are as follows:

1) Very common in the firearms industry at the moment, even among some of the best brands, is the clipped conical baffle. This design has some, but not excessive, cross-jetting to disrupt forward flow. This design is also widely applied to both supersonic and subsonic suppressor designs, making it arguably applicable here. You might at this point be wondering why I’m not opting for the all too common traditional K-baffle, which is very effective in dealing with subsonic flow moderation. The answer is that the simple K-baffle isn’t that effective at sound moderation, comparatively speaking, although it is very easy to machine which explains part of its prevalence. The more complex and efficient K-baffles are very quiet, but induce a lot of cross-jetting which significantly negatively affect accuracy. They also tend to have tonal issues, so while the results are quiet on the meter they’re also shrill and unpleasant. Some companies, notably Dead Air Armament, have overcome this with much testing and design work but for obvious reasons I’d rather not have to extensively optimize an experimental control, because doing so would rather negate its value as a control as well as detract from the central experiment.

2) What if the clipped conical baffle works better than a Tesla Gas Diode at inhibiting forward flow in a suppressor, but is disadvantaged because it is shoved in a fixed-volume design? A scaled down clipped conical baffle stack used as the center core on the same outer core as the gas diode design would be a worthwhile control.

3) When everyone is doing one thing, and you’re doing something else, maybe that is because you’re a genius but more likely it is because you’re an idiot. I’d be foolish not to make a comparably sized design and pack it with an open-cell material like felt or foam which has worked so well for Huggett and DonnyFL. The architecture is trivial to design, so may as well run with it.

4) And, of course, the entree: my Tesla Gas Diode design. I have no doubt it’ll work, but whether or not it’ll work better than the other designs I have no idea.

And that is where things stand for now. There is a lot of time, design work, and testing between here and there. Also this blog post has dragged on long enough. So I’ll wrap it up here. In part two we’ll dive more into the gritty end of prototyping, a few more subtle elements of design, etc. Then in part 3 we’ll finally get to testing, results, and revisions.

The business end of the first gen gas diode moderator on the FX Crown. Note the lighter colored material at the interface between the carbon tube and ends. This is a glow-in-the-dark material, added for style, but could readily be any color/shade, including that of the moderator core thus making it indiscernible. To the right we can also see a rangefinder and this gun’s preferred diet of JSB pellets.