Project - FX Crown Moderator (part 2)

Silent Thunder Ordnance

Tesla Gas Diode Moderator on the front of an FX Crown .22 synthetic with athalon argos optic

You can find part 1 here. This is the second installment of trying to make a novel and effective moderator for the FX Crown based around the concept of a linear Tesla Gas Diode.

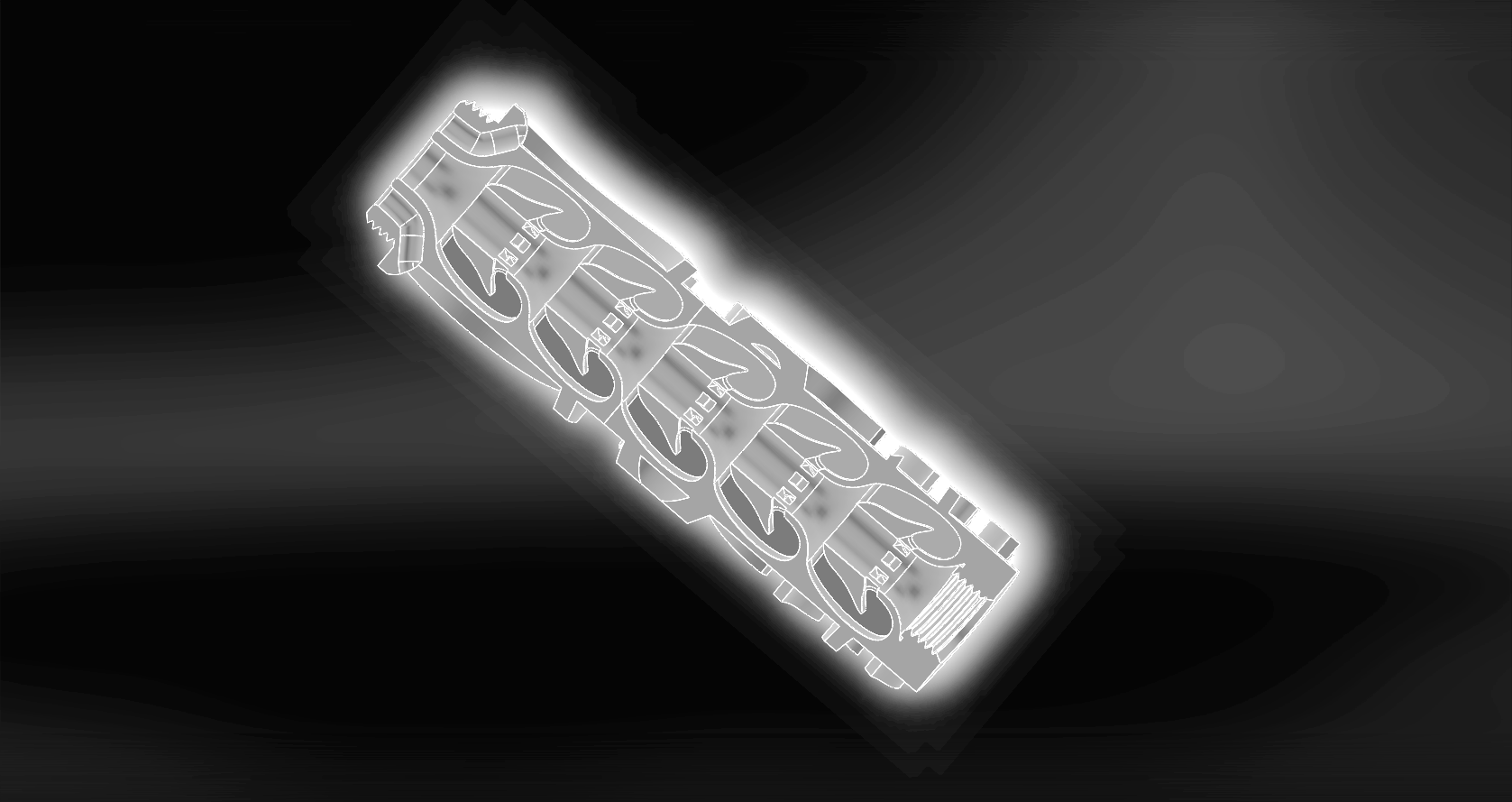

Cutaway of the Tesla Gas Diode design

Having successfully designed and built one, I also built several other designs of various industry standards to compare it against. Those are the common felt/foam from the airgun industry and the clipped conical baffle design common to the suppressor industry (with flow-through around the outside). All that remained was to test them and compare.

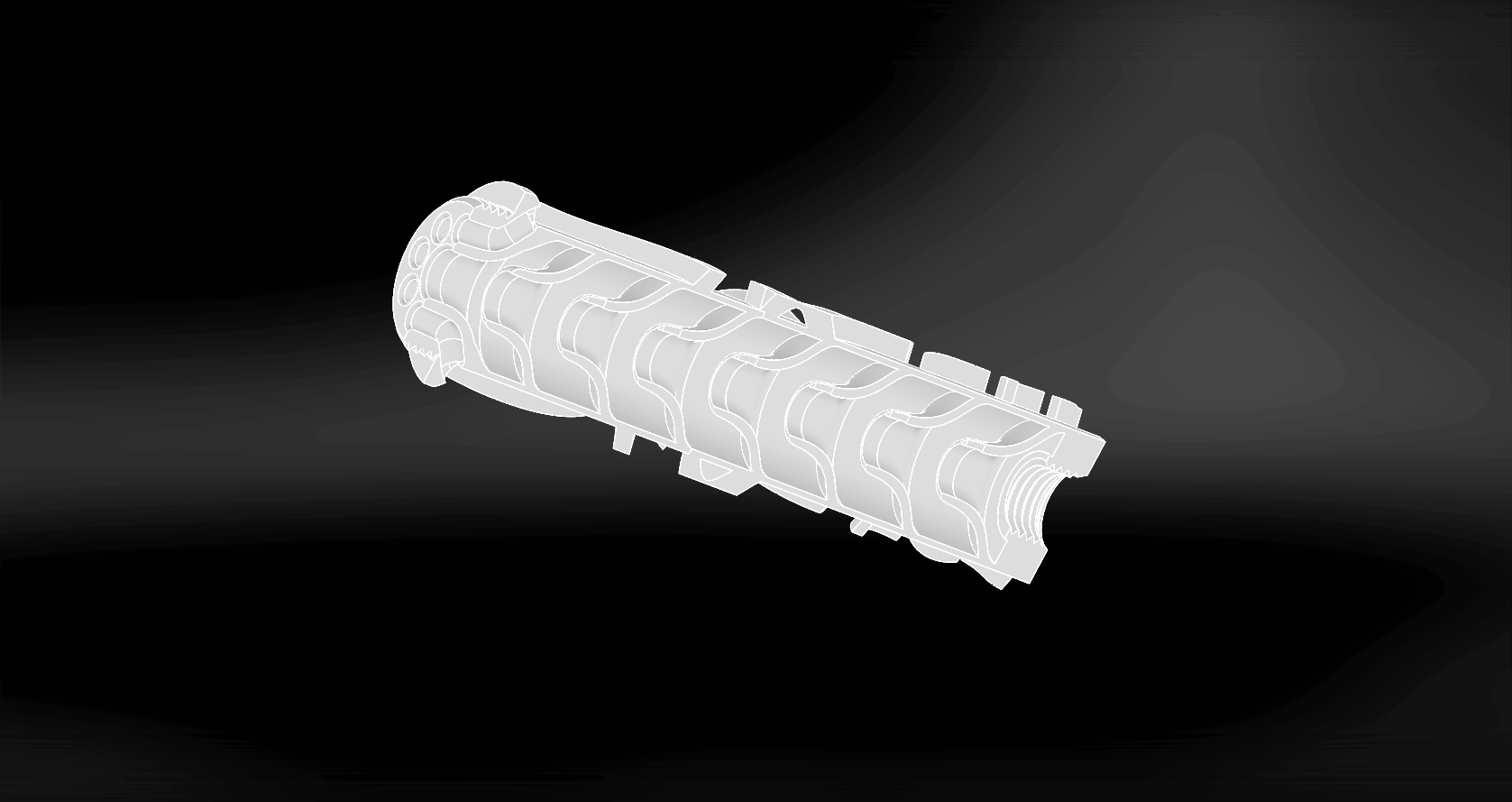

Cutaway of the clipped conical baffle design. Note the blast baffle is un-clipped to minimize POI shift.

So measurement-wise, I went with the suppressor industry standard which is 1.6 meters off the ground, and muzzle 1 meter from the mic. This is done with two tripods, one holding the pickups the other justifying the muzzle of the gun. This assures things are the same every time. Consistency is close to godliness, and if your data is a mess good luck getting anything useful from it. The gun is my FX Crown .22 shooting Crossman Premier HPs, and while I didn't chrono the Crossmans it spits JSB 18.13s at 874fps with +/-3FPS on average. Each configuration was fired 5 times. Six configurations total were tested and they are as follows:

Shroud Collapsed

Shroud Extended

Copper Gas Diode (copper references color, not material)

Silver Gas Diode

Clipped Conical Flow-Through

Foam

Here is what a typical sound data sampling looks like:

Sound sampling from an FX Crown with the shroud extended. Note the secondary peak. This peak appears to correspond to the length of the shroud at the speed of sound. Funny eh?

Aside from having exceptional sampling resolution, 250MSa/s that is to say 250000000 samples per second making it able to sample very very brief sound occurrence, it also can provide other interpreted data such as the most prevalent frequency, the overall length and shape of the event, etc. It is very handy, particularly when developing moderators rather than just comparing them. As you can see each sample has a LOT of data in it, multiple channels, the full spicy chalupa. The result is that, rather than a typical sound meter which is sampling one event one time, each value I present below represents multiple simultaneous samplings of each event (a shot), that event is then repeated (five times per configuration, five shots), and it all is recorded. The result is that there is an immense amount of data generated here, and then has to be post-processed, which is all ultimately distilled down into a single average of the multiple samplings of multiple events. Because my calibration is well out of date, rather than then converting to decibels which would be wrong, I just left them as unit-less numbers. This is perfectly fine for the purposes of this comparison, since I doubt anyone else is running a Bruel & Kjaer to produce assuredly accurate numbers anyway. I realize it is all a bit complicated, but hopefully the single value makes it easy and simple. Side note, these aren't powder burners, so there is no first round pop, and because regs are imperfect on the first shot after storage the gun was cycled to “warm it up” prior to testing.

Less handy were the two el-cheapo meters I had running. I've seen a lot of people taking measurements on airguns and posting it on youtube with these inexpensive meters. When last I did this it was with firearms, and years ago, so I thought maybe just MAYBE newer meters had the resolution and range to measure airguns. Several reviews on the new meter I picked up even said that it "worked great on airguns," one even claimed it compared favorably to an "expensive German meter" on airguns. While I can't speak for every meter out there, having done the testing I can now confidently say that this is not the case on this meter at least, and that while the meter will pop SOME number in response to every shot, and they're remarkably consistent, whatever it is reading isn't the muzzle report. How do I know this? Because every single configuration was within margin of error of each other. That meter claimed every configuration was about 97db average. EVERY. SINGLE. ONE. I don't know what it was reading, but it sure wasn't the muzzle. *shrug*

FX Crown muzzle blast with the shroud collapsed. Very very loud, for an airgun anyway.

Shroud Collapsed - 728

Pretty much what you'd expect here, or rather if you own a Crown, exactly what you've come to know and love. That predictable loud bark. This is easily the loudest test in this series. And it is quite messy, again as you'd expect, because there really is no damping or anything of the sort. Presumably that pressure wave can ricochet up and down the shroud as many times as it wants puffing out the muzzle bit by bit. I'm guessing, just guessing, that the brake and shroud cap act as one in the collapsed position, so there really is nothing here just a reflective tube at both ends. It is possible that by modifying the action end of the shroud stop some significant gains could be seen here, so it isn't just a big sounding tube. Dampers like this could be designed for dual effect, to both eat barrel vibration (improve accuracy) and sound. This might be worth exploring, along with perhaps venting the rear of the Crown shroud...... or alternately replacing the stock shroud entirely with a lighter weight carbon fiber one that is an integral part of the entire sound damping and accurizing strategy.

FX Crown w/ shroud extended

Shroud Extended - 312

Again what you'd expect. It is considerably quieter than the shroud collapsed both because of greater muzzle-forward volume, and it tapers more rapidly because the brake now can act as a choke point between the two chambers as the pressure wave bounces forward and backward. Notice the secondary spike in there. A little napkin math correlates this with the speed of sound traveling the length of the shroud. Cool stuff huh? It is possible, given a longer sampling time, we'd have seen more descending spikes tapering off.

FX Crown w/ clipped conical baffle moderator design.

Clipped Conical Flow-Through - 346

So this was kind of a flow-through outer shell take on the suppressor industry standard of the clipped conical baffle. The clipping diverts flow laterally, making it quieter than your typical symmetrical conical baffle, however it comes with POI shift as I discovered..... in fact over 4 MILs of “repeatable” POI shift. There were two problems with this though, the first that is in pellets this kind of POI shift is destabilizing so it'll cost you some accuracy (unacceptable), and second the crown's shroud is free rotating so any repeatability is also thrown out the window. Hence I didn't do a second pure clipped conical design, because whats the point? Speaking of whats the point, after looking at the numbers you'd have to ask whats the point of this design? It is quieter than the shroud extended, but not by a lot. Given that it is physically the longest design tested by a few milimeters, and has the most baffles, I think we can pass on this conical baffle design for further exploration. It is easy to machine though, so I can see why it is popular.

FX Crown w/ foam moderator. Note the high initial spike and relatively clean sound thereafter.

Foam Fill - 204

Now things are getting interesting. This is my attempt at good performance analogue for the all-too-common foam/felt hair curlers and washer baffles design. It is a relatively thin layer of foam constrained toward the outer surface of the suppressor and exposes maximum surface area, more than the Weilrauch's design. The muzzle end uses the same cap design as all the others, and the threaded rear uses the same flow-through design. To the ear, both my friend and I agreed this design could be the quietest of all six tests. It is hard to tell with these things, so we both were eager to see the numbers, but we both bet that this would win.... somewhat to my chagrin. Looking at the pressure wave, it is very obvious how it peaks very strongly and cleanly initially, and tapers off very quickly. This could be thought of as the visual equivalent of a clean sound moderator, pop and done. We'll get back to this, it becomes important later.

FX Crown w/ gas diode moderator

Gas Diodes

Cu - 192

Ag - 194

I combined these, as they're identical designs in essentially identical materials. (just differing color) In essence, they should be the same, and testing bore that out. It is always nice though when something pans out, in this case repeatable manufacturing being repeatable and performing consistently. By now you've seen that the numbers are lower, so the moderator is in fact quieter! All my crazy scheming worked. Why then did we both think the foamie was quieter? Remember when I said the human ear is really bad at judging sound pressure level? Well that certainly has something to do with it, your ear just can't tell what is louder than what very effectively, in much the same way your eye can't easily judge how heavy a cow is but a scale can do it accurately all day every day. There is another element I think is at play here though. The foamie had a higher initial spike, with no complex architecture to retard it, however once that passed through it tapered rapidly. The gas diode conversely shows that it is doing EXACTLY what it is supposed to be doing: extending the length of the event by holding that pressure and releasing it slowly. This means it produces sound for longer, which is a good way to fool an ear into thinking something is louder. A hammer hitting a nail doesn't sound that loud, but make something that loud continuous and you'll find it deafening. While that is an extreme example, it illustrates the point quite nicely how something which is quieter but lasts a little longer can sound about the same or even slightly louder than something which is technically louder than it is.

Exterior of gas diode flow-through area.

So there it is, in its full spicy glory. As with everything in life and science, the answer only raises more questions, more avenues of inquiry. But for now I've accomplished what I set out to do, and to my pleasure and surprise the countless hours of designing and testing and revising all built on a harebrained idea borrowed from the eccentric genius Nikola Tesla from a century and a half ago.