Project - Print Durability Demonstration

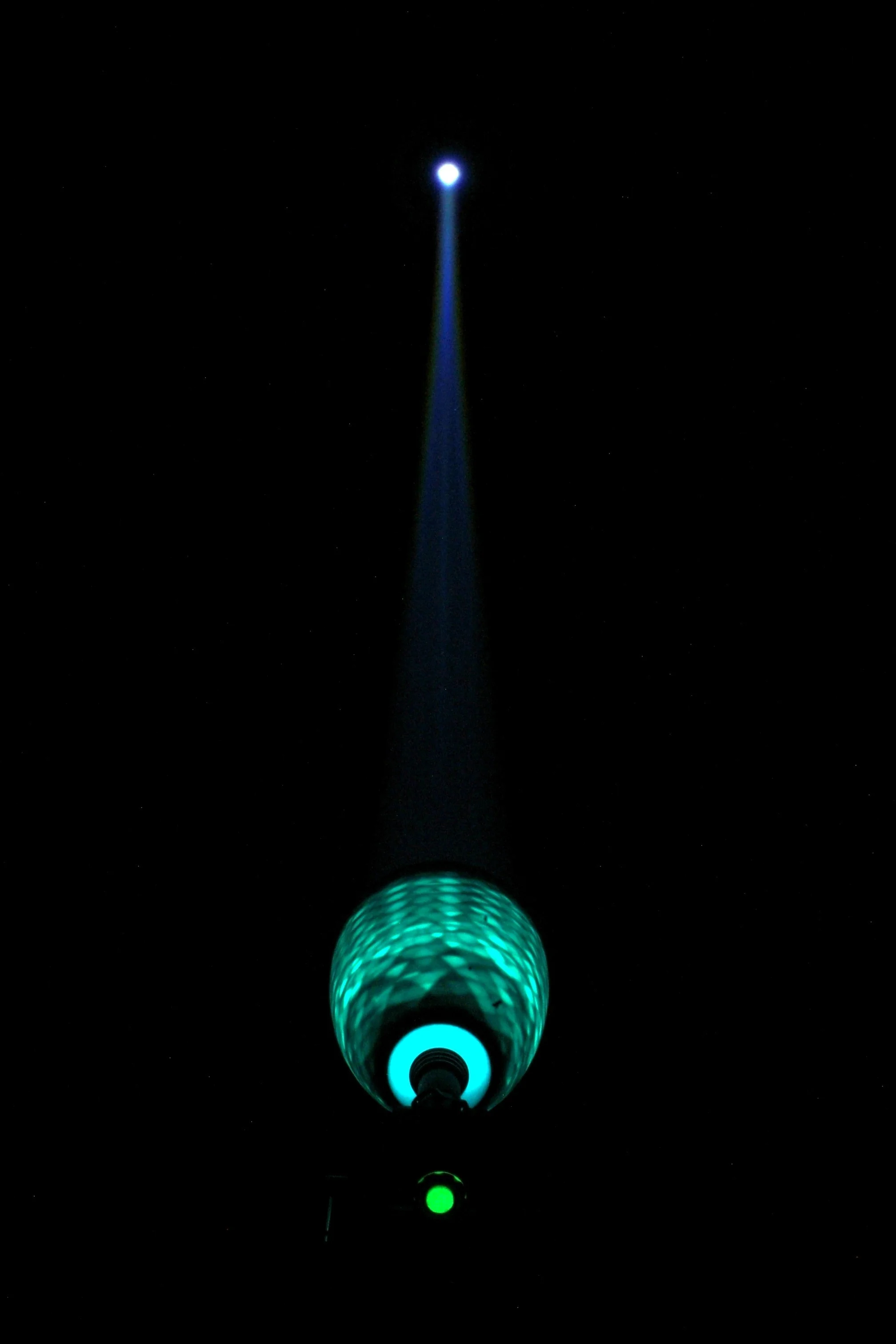

Silent Thunder Ordnance

With the advent of new technologies come obvious questions: how good is something? Will it last? How is this different from a consumer grade item? In the case of our lights with major 3D printed components, we've repeatedly gotten these sorts of questions, no doubt spurred with less-than-positive experiences with prints off of earlier more fragile 3D printed technologies (such as early SLA) or brittle PLA printed parts off consumer grade 3D printers. We can say that these prints are different, they're done on custom built professional grade 3D printers, strong and impact resistant polymers are used, structures are designed for durability, etc, but what about a more tangible demonstration?

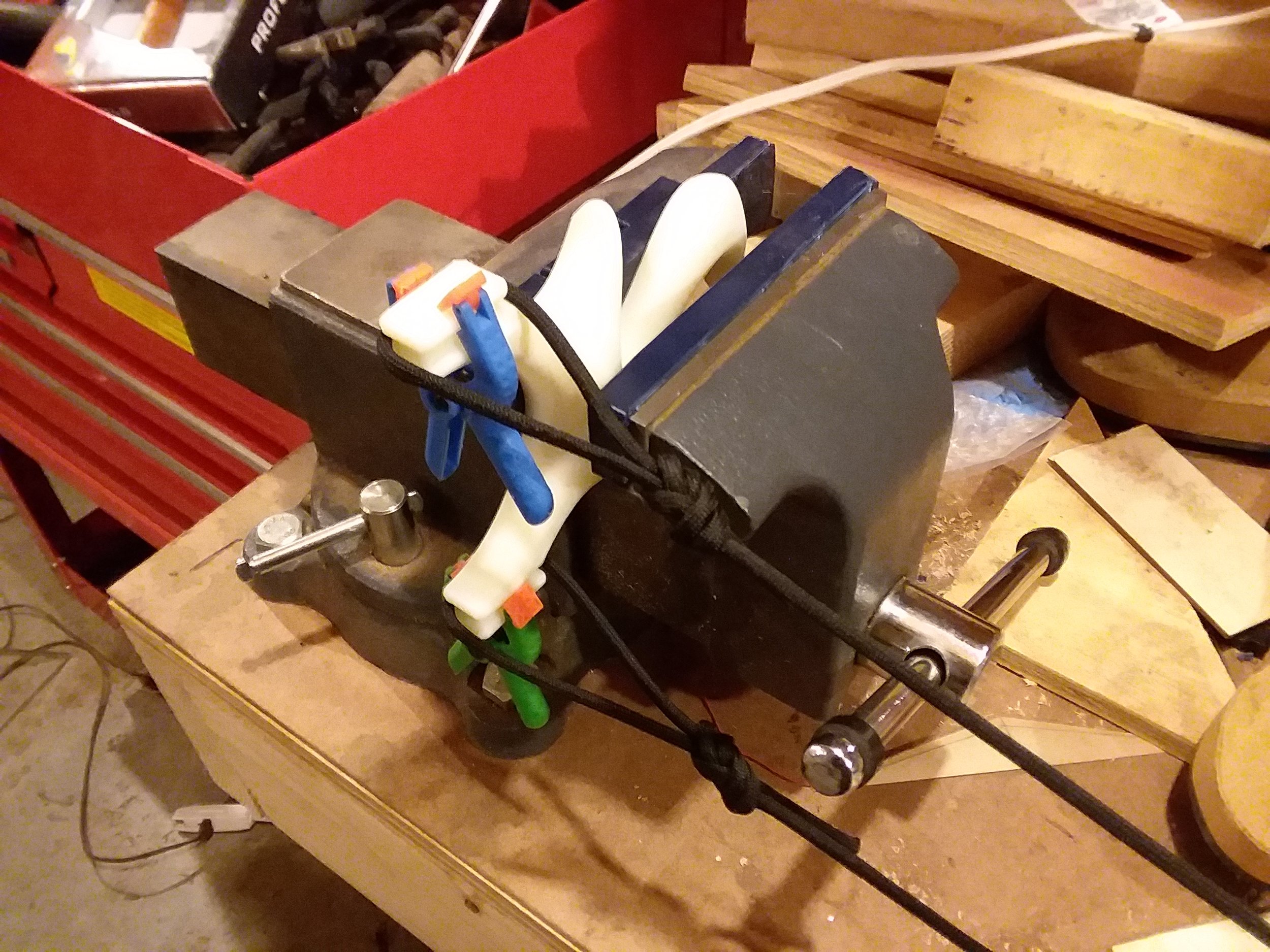

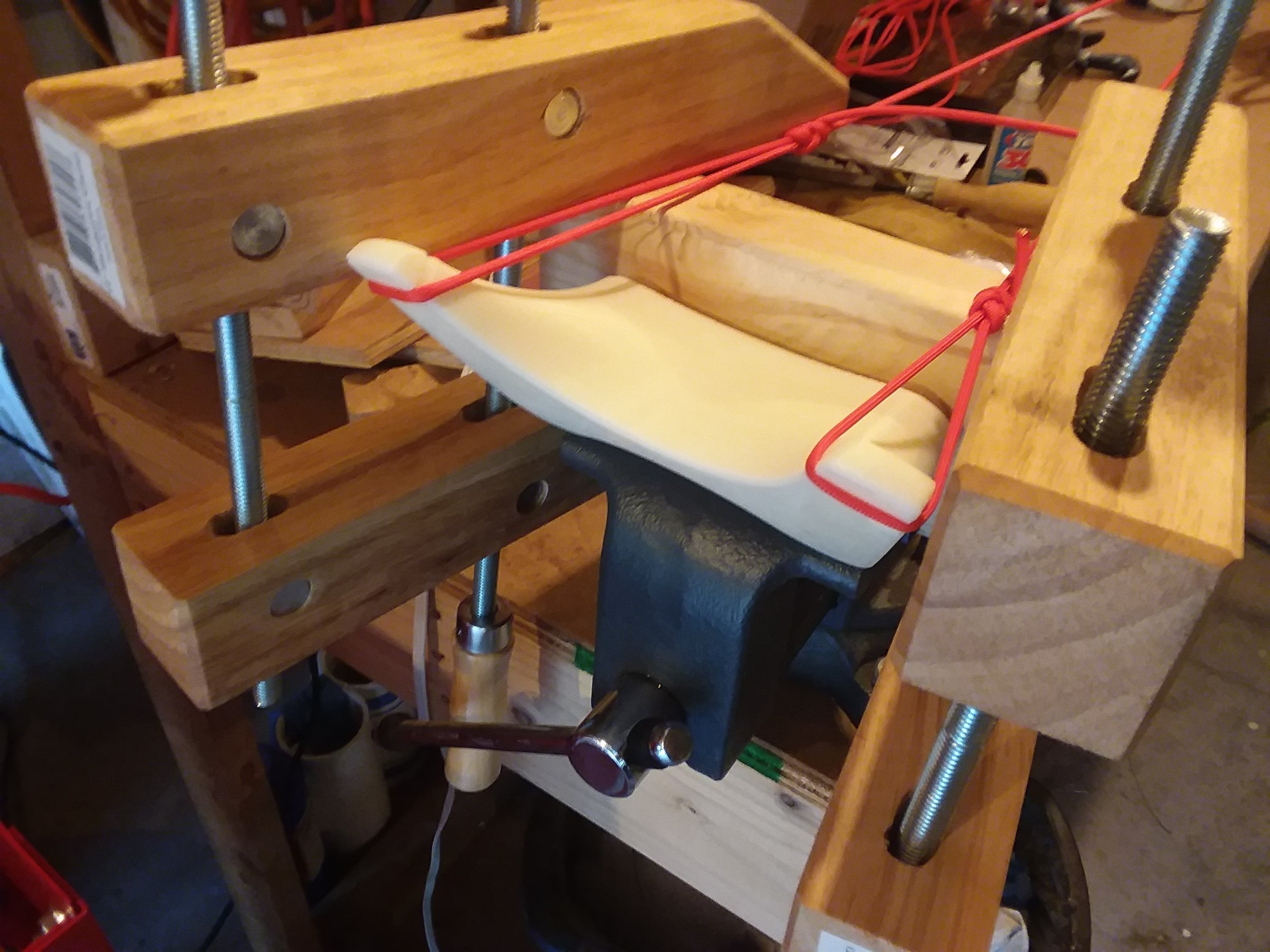

A recent personal project from a member of STO was an excellent demonstration of this performance. This individual wanted to make a slingshot, print it out, but before use wanted to test strength. After all, if the fork on a slingshot were to break off the results would be unpleasant at best, dangerous at worse. The design is based off the Bill Hays Harpy, which has very slender and comparatively weak forks. So we clamped it up in a vice, attached some paracord to the forks, put a load cell in the middle, attached the other end to a winch, and pulled until it broke.

Remember this is the same material we make most of our flashlights out of run on the same machines. The result? Well for starters we had to get a larger load cell, as our standard 50 kilogram one wasn't enough. Failure occurred at 156 kilograms (344 pounds), and amazingly our camera captured the PRECISE moment of failure. Keep in mind this wasn't a solid print, an exercise in maximizing strength, or anything else like that. Just an experiment to see what a fairly normal print profile would endure. Remember this slingshot only weighed 41 grams, meaning it held 3.6 thousand times its own weight.

Funny enough, we had the opportunity to repeat the experiment on a slightly more robust slingshot fork design. Our load cell is only rated to 300 kilograms. We chickened out at 260 kilograms (570 pounds force), with NO FAILURE TO THE FORK WHATSOEVER. Below is a gallery of the before, after, and a lousy peak force image taken from far far away behind a tool cabinet.

So we hope this goes a little distance toward answering the question of how strong our printed parts are. They're certainly not indestructable, nothing is, however they are remarkably robust.