Project - Silent Laminar Flow Fan

Silent Thunder Ordnance

I'm not the kind of guy to spend $500 on a blow job at Walmart..... even if it's from a guy named James Dyson.

The issue with the Dyson fans is that they’re pretty inefficient, loud, and not what you’d call cheap. So if you want to get blown in your sleep without disturbing your significant other, a better solution will be required. This project was embarked on with the explicit goals of being:

Silent (won’t bother you or your SO while sleeping)

Ultra-low energy consumption (remember ultimately the point of this is to cool you off, so a fan which eats a hundred watts or more may feel cool to sit in front of, but is ultimately generating a fair bit of heat)

Focused and smooth air (so it can blow on you, but not your SO who doesn’t like it, again minimal disruption. We’re going for a gentle Hawaiian breeze here.)

Inexpensive (it is a total experiment, so starting with a couple hundred dollars in parts just to see if something is viable stinks!)

Adjustable for all angles (so you can aim it EXACTLY where you want it)

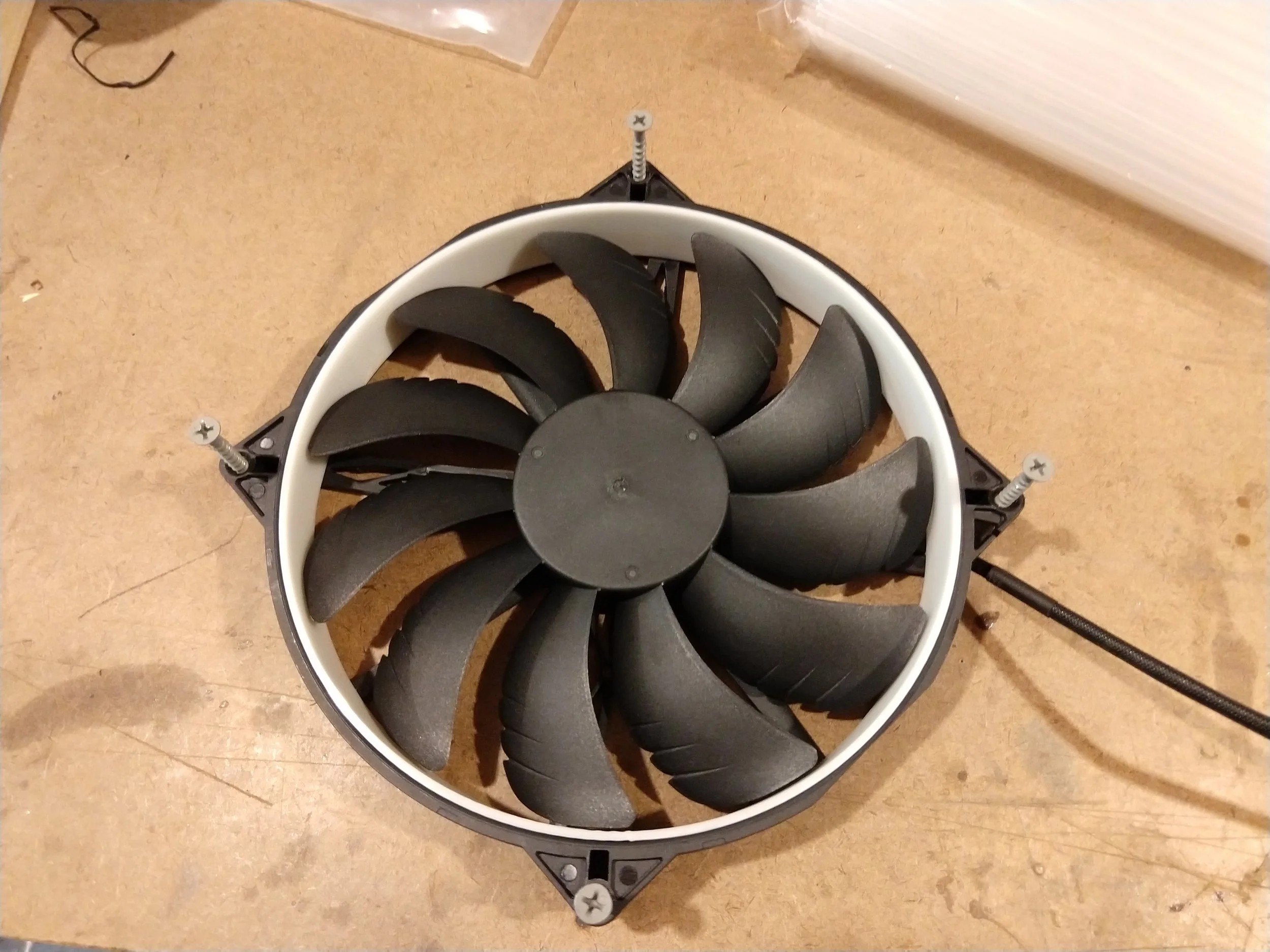

So objectives set, how to go about it? To solve this, we’re going for a quick and dirty project here, completed in a day thanks to rapid prototyping. Best to start with a base. Designing impellers and fans is a bit of a process, so lets go with something off-the-shelf. Computer fans are notoriously inexpensive, efficient, reliable, and well documented regarding their performance and noise level. I went with a Thermaltake 200mm case fan, two of them actually, for all of the above reasons. The exact model number is CL-F015-PL20BL-A.

And if you wanted silent air at a cheap price alone, you could very easily just build a mount for these and call it good. But bladed fans deliver their air, not continuously, but in pulses. They also tend to spread their air out quite a lot, producing turbulent flow. The optimal would be, not turbulent, but laminar flow. So the next obvious step was to set about building an integrated laminar flow head w/ mount for the Thermaltake fan.

Thanks to the miracle of rapid-prototyping, this head was ripped out quickly and fit first try. Note the dovetail at the bottom. Tripod ball heads will point in all directions, and cheap ones are available for a song, so an Arca Swiss clamp seemed like an obvious choice rather than trying to fabricobble some sort of head. I should note though that, if you had one kicking around, one of those old school adjustable desk lamps with the coil springs on the side would also work well for this application, concealing the wires as well.

So at this point you might be saying something along the lines of “great, but that isn’t laminar flow, that is just some vague stumpy ducting. What gives?” Right you are, in the famous words of Brittney Spears though “I’ve got a plan.”

So you want a whole bunch of smooth parallel thin walled tubes. What better way to kill two birds with one stone than to use soda straws? I know I’m doing my part to help us use the 6 bajillion straws Americans allegedly consume per year. (it is approximately 500 straws per fan, if you were wondering)

Having shoved all the straws together, I encountered my first problem: the relatively short duct required the straws shoved in and compressed rather forcefully. This meant the friction fit holds them in place, just as I had intended, however it also means they have a certain flare outward at the top. Not good. The other problem, running the fan, is that apparently these Thermaltake fans are absolutely piss poor at positive pressure applications, even ones as mild as this.

The flare at the top was an easy fix, just a retaining ring can be press fit around the sraws and nicely constrains them. Problem solved.

The pricklier problem of the thermaltake fans has to do with blade velocity, blade geometry, and ductwork. I could run the fans harder, I could design new blades, but the low hanging fruit is to clear the MASSIVE almost 3mm gap between the blade tips and the fans. A surprising amount of air can be felt exiting the intake side of the fan through precisely this gap.

This one took me two tries to get toleranced correctly, and even still there is about 0.5mm of under-utilized space so I could hit it a third time for even more performance. Allegedly the increase in performance is exponential as the blade tips approach the ducting. This, for now though, mostly resolved the problem.

So how does it work you might be asking? Well, as far as flow goes an inexpensive (read as inaccurate) anemometer I had kicking around measures the output as about 3.5mph at the output (straw) side. Compare that to the 5mph one of these fans, unmodified, produces on the same (again, innacurate) anemometer. Perhaps more importantly is the subjective impression, which is that even 7 feet away there is still a distinct gentle and very smooth feeling breeze. The whole assembly runs in almost complete silence.

The other question is, of course, one of power consumption. Looks like two of these fans running together is 6.7 watts, or about half one of those crappy “save the world” LED lightbulbs which outputs an advertised 60 lumens and you almost believe them. So that is pretty good.

So there it is, cheap, quick, smooth air wafted silently from any angle all for less power than the vampire draw of all those phone chargers you have plugged in all around the house. In the immortal words of George Bush “mission accomplished!”